- +86 13957580925

- 510515850@qq.com

- adela0928@163.com

Sewing polyester fabric can be a rewarding endeavor, allowing crafters and creators to produce durable and versatile garments or home décor items. However, working with this synthetic fiber comes with its unique set of challenges. Polyester is known for its strength, resilience, and ability to hold color, making it a popular choice among sewers. Yet, achieving the best results requires an understanding of the material's properties, proper techniques, and the right tools.

In this article, we will explore effective strategies for sewing polyester fabric, including tips on needle selection, thread choice, and stitching methods that work best with this type of fabric. Whether you are a beginner or an experienced sewer looking to refine your skills, understanding how to properly handle polyester can greatly enhance your projects. By implementing these techniques, you'll be better prepared to tackle various sewing tasks and create beautiful items that stand the test of time.

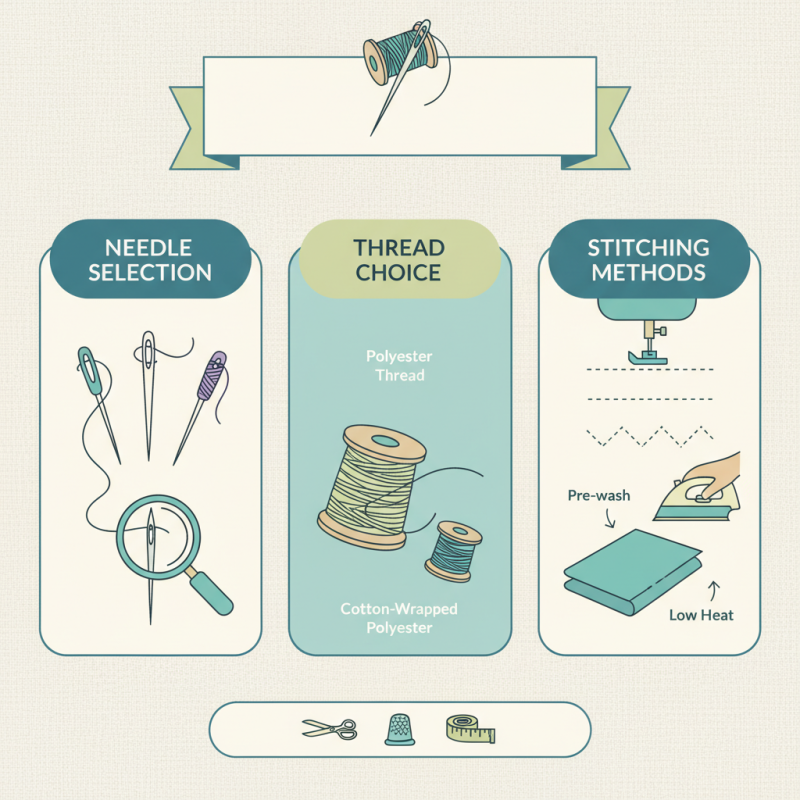

When sewing polyester fabric, selecting the right tools and materials is crucial for achieving optimal results. Start with a lightweight and sharp needle, such as a universal or microtex needle, which helps prevent snagging and allows for smooth stitching. Additionally, using polyester thread can offer better compatibility with the fabric, providing a consistent finish and reducing the risk of breaking during the sewing process. Always ensure that your sewing machine is properly threaded and adjusted to accommodate the unique properties of polyester.

In terms of cutting tools, invest in a good pair of fabric scissors or rotary cutters that are designed for precision. This will help you achieve clean edges, which is essential for preventing fraying and ensuring that the fabric lays flat. Another important consideration is using a cutting mat to protect your work surface and extend the life of your blades. Finally, when preparing your polyester fabric, consider using pins or clips instead of staples, as these can keep layers in place without damaging the material. By carefully selecting your tools and materials, you can ensure a smooth sewing experience and create stunning polyester projects.

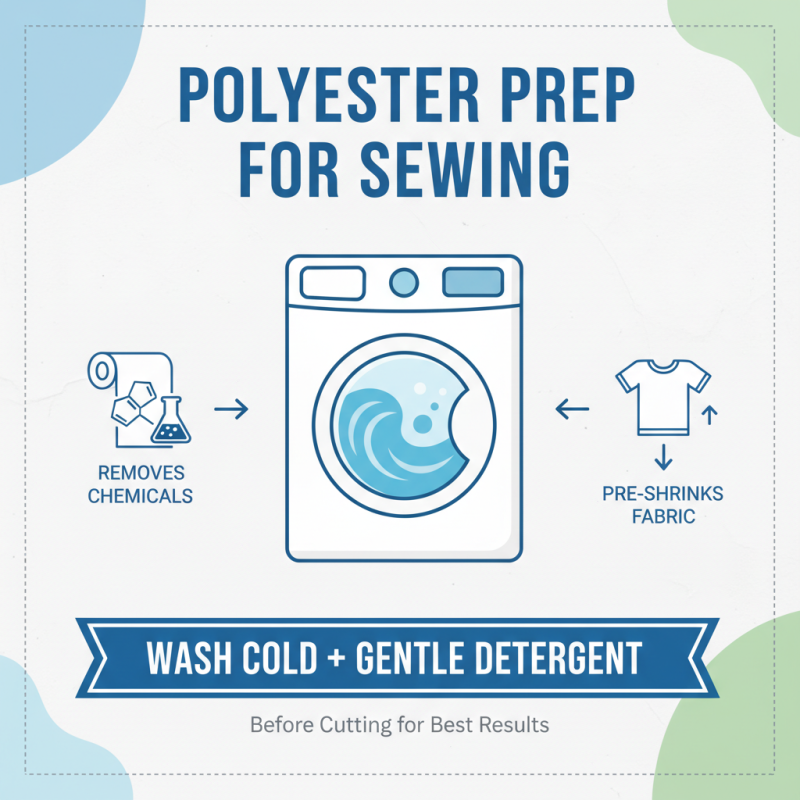

When preparing polyester fabric for sewing, the first crucial step is washing. Unlike natural fibers, polyester can retain a significant amount of finishing chemicals from the manufacturing process, which can affect the fabric's performance and how it accepts dyes. To ensure the best results, it's advisable to wash the polyester fabric in cold water with a gentle detergent before cutting. This step not only removes any residues but also pre-shrinks the fabric, minimizing the risk of size changes after your project is completed.

Cutting polyester fabric requires particular attention to detail due to its slippery nature. It's recommended to stabilize the fabric with pattern weights instead of pins, which can create unsightly holes or distort the material. Use a sharp rotary cutter or fabric scissors to make clean, precise cuts, and consider marking your pattern with tailor's chalk instead of pens or markers that may bleed or smear. Additionally, always cut with the fabric right side up to maintain the integrity of the fabric surface, ensuring that your finished project looks professional and polished.

When sewing polyester fabric, selecting the appropriate stitch types is crucial for achieving durability and a polished finish. Polyester, known for its strength and resistance to stretching and shrinking, requires stitches that accommodate its unique properties. According to a report by the Textile Research Journal, using stitches such as the stretch stitch or a zigzag stitch can enhance the flexibility of seams, allowing for the fabric's natural elasticity to be maintained. These stitches help prevent the fabric from puckering, which is a common issue when using straight stitches on polyester.

Additionally, the choice of needle and thread contributes significantly to the sewing process. The American Sewing Guild suggests using a universal or ballpoint needle in sizes 80/12 or 90/14, which reduces the chances of skipped stitches or fabric damage. Meanwhile, polyester thread is often recommended, as it matches the fabric's properties, providing both strength and flexibility. The combination of the right stitch type and appropriate needle and thread ensures that seams remain intact even under stress, making it essential for projects involving activewear or household items. By adhering to these guidelines, sewers can achieve optimal results when working with polyester fabric.

When working with polyester fabric, proper seam finishing is essential to prevent fraying and ensure a polished final product. Polyester, while a popular synthetic choice known for its durability and resistance to wrinkles, can be prone to fraying at the edges, especially if the cut is not managed well. According to a report by the Textile World, approximately 30% of textile waste arises from poor finishing techniques, making effective seam finishing a critical aspect of garment construction.

One technique to consider is the use of a serger, which can trim excess fabric while simultaneously enclosing the raw edges with thread. This not only prevents fraying but also gives a professional finish to seams. Industry data shows that garments constructed with properly finished seams can experience up to 50% more durability during wear and washing. Additionally, applying bias tape along raw edges is another effective method for preventing fraying. This approach allows for added strength and can bring a decorative element to your project, should you choose to use contrasting colors or patterns.

For those who prefer a manual approach, techniques such as pinking shears or zigzag stitching can also suffice. A study from the American Sewing Guild indicates that seam finishing methods like these can enhance fabric longevity, extending the life of garments by an average of 20%. Implementing these techniques not only helps maintain the integrity of polyester fabric but also improves the overall quality and longevity of the finished product.

| Technique | Description | Advantages | Disadvantages |

|---|---|---|---|

| Zigzag Stitch | A stitch pattern that creates a zigzag line, preventing edges from fraying. | Flexible and prevents fraying effectively. | May not be suitable for all fabric weights. |

| Overlock/Serger | Uses multiple threads to stitch and trim edges simultaneously. | Creates a professional finish; fast and efficient. | Requires a specific machine that may be costly. |

| French Seams | A seam technique that encloses raw edges within the seam itself. | Very neat finish; ideal for lightweight fabrics. | Time-consuming; requires extra fabric. |

| Bias Binding | Attaching a strip of fabric to cover the raw edge. | Enhances durability and provides color contrast. | Can be bulky if not done properly. |

| Pinking Shears | Cutting the fabric edge with zigzag shears to reduce fraying. | Simple and easy to do. | Not as effective as sewing techniques; may still fray. |

When working with polyester fabric, proper ironing and pressing techniques are essential to maintain its integrity and appearance. Polyester is sensitive to heat, and using too high a temperature can lead to melting, shiny spots, or an overall distorted fabric. To avoid damage, it is crucial to set your iron to a low or medium heat setting, ideally using the synthetic setting when available. Always check the care label for guidance on heat resistance before proceeding.

To protect the fabric further, consider using a pressing cloth—a thin layer of cotton or muslin placed between the iron and the polyester. This barrier absorbs excess heat and prevents direct contact, reducing the risk of scorching or melting. Additionally, steam can be your friend when working with polyester. Instead of applying a pressing motion, gently hover the iron above the fabric and use the steam function to relax any wrinkles. This method minimizes direct heat exposure while achieving a smooth finish, thus preserving the fabric's quality and sheen.